Our selection of self-regulating pressure control valves have been designed for use in broad range of applications including, food and beverage processing, tank blanketing, steam cleaning, oil and gas plants, water supply, chemical transfer and more.

Since 1885, our partner Mankenberg, have always been distinguished in their field, with unrivalled expertise and renowned technical know-how in providing fully optimised solutions with their self-regulating valves.

What are Self-Actuated Regulators?

Self-acting pressure reducers are simple valves offering very accurate pressure control, whilst being extremely easy to install and maintain. They can control the pressure upstream or downstream of the valve without requiring external energy input, such as pneumatic or electrical control elements, hence the term “self-actuated”.

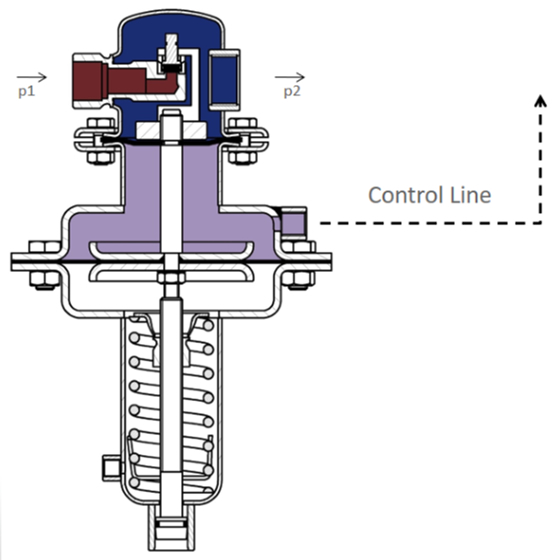

Taking our time-tested DM652 pressure reducing valve as the example, this unit is responsible for reducing a high and frequently fluctuating pressure to an adjustable constant pressure downstream of the valve. This is also referred to as reducing an upstream pressure (P1) to a lower, controlled downstream pressure (P2). A spring keeps the valve open and this closes as the outlet pressure rises.

How do Self-Regulating Valves Work?

Again, utilising the DM652 pressure reducing valve as the example, this specific model is a diaphragm-controlled spring-loaded and balanced proportional control valve for a broad selection of universal applications. The outlet pressure required is balanced across the control unit by the force of the valve spring (set pressure). As the outlet pressure rises above the set pressure using the adjusting screw, the valve cone moves around towards the seat and the volume of media is reduced. As the outlet pressure drops, the valve control orifice increases; when the pipeline is depressurised, the valve is open. Rotating the adjusting screw clockwise increases the set outlet pressure.

The DM652 model is required to have a sense line (or control line) connection installed on-site. This guarantees an exact regulation on the outlet pressure if the system should see any small back pressures. Through this line, the back pressure is reduced directly into the system where the pressure should be at a constant set value. Additionally, any turbulence arising in the valve housing which could lead to control accuracy, is avoided.

For a more detailed look into how a pressure reducing valve functions in a pipeline, please watch our video below:

Advantages of Self-Actuated Valves

Our self-acting control valves have always been well-known for their affordability, functional reliability and long operational lifespan. Since 1885, Mankenberg has been standing for self-acting pressure regulators which are designed to act as “fit and forget” solutions and have worked tirelessly to convince customers through their unrivalled quality, excellent price/performance ratio and high on-time delivery performance.

The special advantages of our self-acting valves can include:

- High Safety Levels – Based on over 100 years of experience, the time-tested and proven designs of these valves offer end users continued functionality, even in the event of a power failure, as there are no external electrical inputs required for operation. As the valves are completely self-acting, they offer quick response times and present no risk of maloperation.

- Low Cost of Ownership – Our valves offer customers an extremely low cost of ownership. Thanks to the specialist design of the valve bodies, maintenance is made extremely easy. All service kits for standard valves are kept at a low-cost level and in most cases, are readily available off-the-shelf.

- Easy Assembly and Operation – Installation and assembly is made easy with our valves, with most standard valves having a very low net weight and compact design. Valves can be positioned and installed even in ‘difficult to navigate’ areas. The sturdy structures of the valve bodies make them suitable for operation in the harshest environments and demanding applications.

- Great Sustainability – With the right consultation for us, our valves are designed to have the longest operational lifespan. With the correct selection for your individual application, these valves offer customers longevity, limited maintenance and hassle-free installation.

Types of Self-Operated Control Valves

- Pressure Reducing Valves – pressure reducing valves reduce a high and frequently fluctuating pressure to an adjustable constant pressure downstream of the valve. A spring keeps the valve open and this closes as the outlet pressure rises. We offer a range of pressure reducers suitable for applications from industrial to ultra-high purity.

- Back Pressure Valves – back pressure regulators (as referred to as overflow valves or pressure sustaining valves) control an adjustable constant pressure upstream of the valve. A spring keeps the valve closed, and as the inlet pressure rises the valve opens. These pressure sustaining valves are also available in cast materials for engines or pilot-operated for large pipelines.

- Bleeding and Venting Valves – bleeding and venting valves omit air or gases automatically from/to tanks, vessels or pipelines. They are float-controlled valves which close as the liquid level rises and open as the level falls. Again, these valves operate independently from any external pneumatic or electrical inputs.

- Condensate & Steam Traps - steam traps are again, float-controlled valves, responsible for automatically draining condensate without loss of steam or gas. They operate instantaneously inside systems and are not affected by backpressure or pressure fluctuations. Our KA2 autodrains are the ideal solution for knockout pots on biogas applications, where ATEX approval is required. We also have larger cast versions for boiler installations.

- Vacuum Breakers – vacuum breakers protect vessels and pipelines against vacuum. A vacuum can build up when a system is being drained, when it cools down or when a pump fails. Vacuum breakers are responsible for protecting tanks, vessels and pipelines from implosion. We can also offer customised vacuum and differential control valves for bespoke applications.

How to Size a Self-Actuated Pressure Regulator

There are multiple different technical factors to consider when selecting a self-acting pressure control valve. The main operating parameters needed to correctly size a unit are as follows:

- Inlet Pressure (P1 or Upstream Pressure usually in BAR or PSI)

- Outlet/Control Pressure (P2 or Downstream Pressure usually in BAR or PSI)

- Flow Rate (Q usually in Nm³/h or SCFM)

- Media Temperature (T usually in °C or °F)

- Media (To calculate the Specific Gravity or Molecular Weight/Density)

These operating parameters are required to correctly calculate a KVS (or CVS) for either a pressure reducing valve or pressure sustaining valve (back pressure regulator). It is imperative that the correct KVS factor is selected for a pressure regulator to ensure that the desired flow-through the unit is met.

By providing us with these values, we can utilise our extensive calculation tools to size and suggest on a suitable pressure regulator. You can also view our more detailed valve sizing guide by clicking here.

Some of the other important factors to consider when selecting self-acting regulators are as follows:

- Materials – what construction materials should be used? This includes both the body material and any other wetted elastomer materials (such as the body and cone gaskets). All our self-acting control valves are typically constructed from deep-drawn 316L Stainless Steel (1.4404), providing end users with excellent surface quality, high corrosion-resistance and an overall lightweight and compact unit. Before selecting a suitable construction material, you may need to consider both the flowing media and installation environment. If the unit is going to be used with particularly aggressive media or installed in demanding environments, it would be worth considering higher grade alloy materials such as Super Duplex (1.4410/1.4501), Duplex (1.4462) or Titanium (3.7025/3.7035) to ensure a long operational lifespan of the control valve.

Additionally, this also applies to the gasket/elastomer materials. If the standard EPDM will not work for your media, we can look at utilising FKM, FEPM, PTFE and more to ensure complete fluid compatibility.

- Connections – what is the line size the unit needs to fit on? Typically, most of our standard self-acting regulators range from sizes 1/2” up to 6” (or DN15 to DN150 in Nominal Diameter) and are available with a broad range of connection options including threaded, flanged, weld and other special connections.

As part of our catalogue offering, we can offer G Threaded (BSPP), NPT Threaded, DIN Flanges to EN 1092-1/11 Form B1, ANSI Flanges to RF, FF and RTJ, Welding Ends to ASME 16.25, DIN and ISO, Aseptic Clamps to DIN and ISO, Tri-Clamps to ASME BPE and more.

- Special Considerations – are there any special conditions that may affect the choice of unit? Will the unit be installed in harsh environments? Do you require a leakage line or gauge connection? Are there any specific cleaning, testing or certification standards needed (such as Oxygen Degreased, FDA Conformity or Pressure Testing)? Do you have a specific noise limit for the valve? The more detail you can share with us, the better we will be able to advise you.

Self-Actuated Valve Applications

Our self actuated valves can be considered for a huge selection of applications and industries, from industrial to R&D/high-tech to UHP environments. Some of the typical industries and applications we work with are as follows:

- Food & Beverage and Pharmaceutical – including steam cleaning for bottle filling plants, tank blanketing for food storage vessels, water disinfection with ozone, CO2 regulation for beverage lines, sterile air supply into tanks and potable water supply in centrifuge test stands.

- Oil & Gas – including compressed air reduction for deep-sea oil drilling, ventilation and bleeding of pipelines for oil tank depots, pilot-operated pressure control in gas compression stations and high oil pressure control in turboexpanders.

- Chemical & Petrochemical – including tank blanketing in petrochemical plants, pressure reduction of corrosive fluids and pilot-operated explosion protection for Nitric Acid tanks.

- Marine & Defence – including ventilation of pipelines for the loading of oil onto ships, pipeline surge protection at seaports and pressure control of diesel in ship engines.

- Renewable Energy & Alternative Fuels – including recirculation of saline reservoir water into the ground and safe discharge of condensate in natural gas pipelines.

Typical Installations for Self-Acting Pressure Reducers

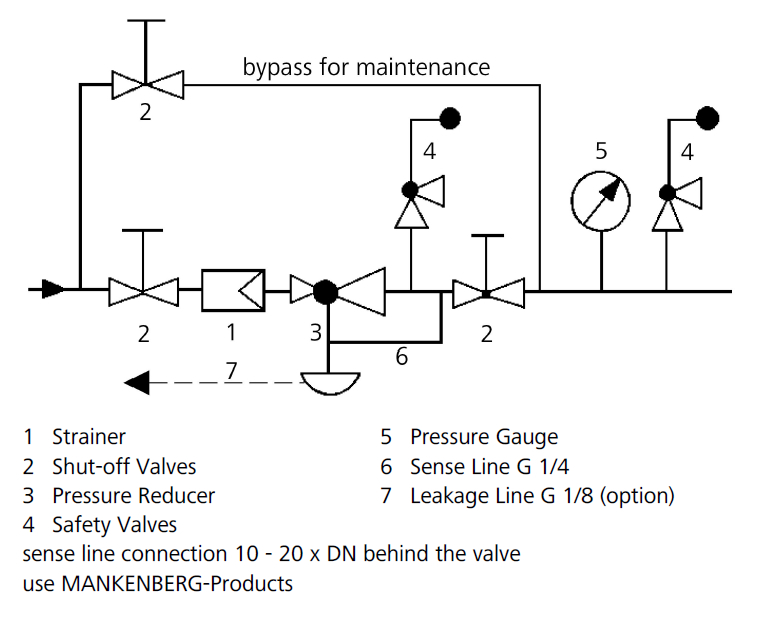

The typical recommendation installation can depend on the type of self-acting valve you are looking for, however based on requiring a pressure reducing valve we often see the following setup:

It is recommended that a filter/strainer is installed upstream of a pressure reducing valve to ensure any particulate or contamination is removed from the line before the media passes through the valve. Shut-off valves (ie. ball valves) should be considered in the event you need to isolate the flow. Safety relief valves should be considered for installation downstream of the regulator, in the unlikely event of a complete valve failure (failing open), a safety valve will be pre-set to crack open and divert the pressure/flow away from any protected equipment further downstream. Additionally, pressure gauges, sense line connections and leakage line connections can all be considered depending on your chosen valve/application requirements.

Your Self-Actuated Control Valve Supplier in the UK

Our range of self-acting valves offer our customers a broad selection of options and configurations to meet almost any application. To explore our full range of self-acting valves in more detail, please visit our category page here.

For technical support on selecting the right solutions for your application, please do get in touch with our experienced team here.

Do you have an urgent requirement? On certain standard configurations for models DM652, DM505, DM555, UV3.5, UV5.1, EB1.12, EB1.32 and KA2 we can offer a fast delivery time. Sized, built and delivered according to your specifications….let us help solve your problem today.