ULS-200 Solid State Point Level Sensor, developed for the most rugged aqueous, oil and hydrocarbon-based applications. Combining the very best of what existing sensor types offer as an all-in-one sensor technology.

The ULS-200’s sealed construction meets the IP6K9K rating for high-pressure wash-downs. It covers a wide temperature range of -40°F to +257°F (-40°C to +125°C) and a high-pressure range of 300 PSIG (20 bar) to meet the most extreme conditions. Shock and vibration resistance makes the ULS-200 the best choice for mobile applications.

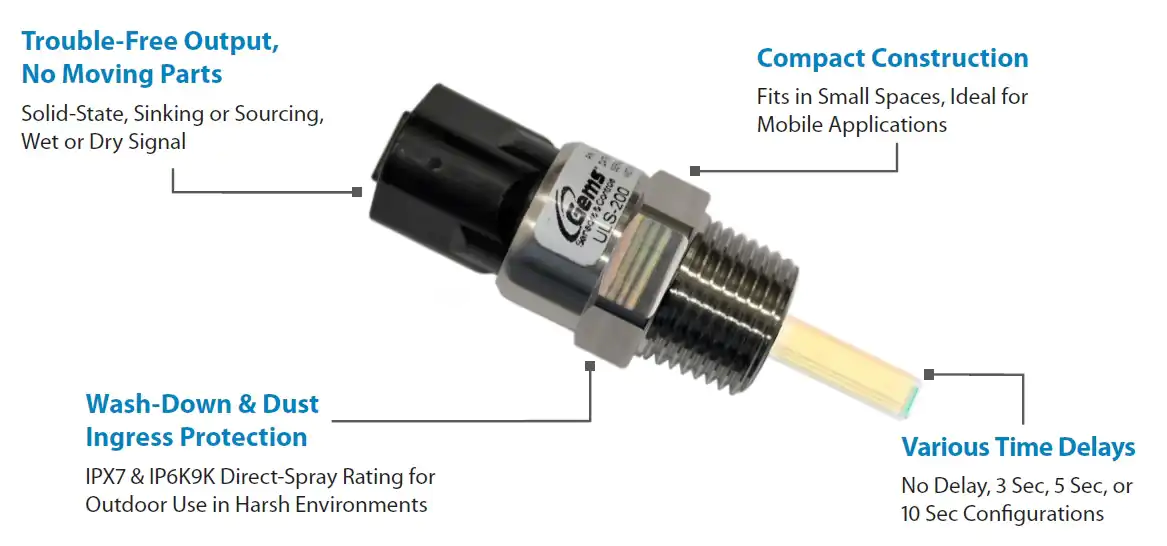

The ULS-200 level sensor utilises a solid-state output for point-level sensing with high accuracy and repeatability. Without mechanical moving parts, the sensor lasts much longer than common float-type switches which are prone to wear and can fail over time.

Configure the ULS-200 for no delay, 3 sec, 5 sec, or 10-second delays to fit your application requirements. Well suited for mobile equipment to prevent false signals caused by sloshing or turbulence. These are standard configurations available when ordering – not specials!

The Gems’ ULS-200 works with a wide variety of media. It eliminates failure caused by moving parts and works well in high-viscous, high-pressure, humid, and reflective applications. It does not rely on specific gravity or conductivity. It simplifies product selection and reduces inventory with ONE common sensor type to replace them all.

Features & Benefits:

Technical Specifications:

Example Applications:

To watch our introductory product overview video, please see below:

Our partner Gems Sensors is a global supplier of sensing and control solutions. Gems designs and manufactures a broad portfolio of liquid level, flow and pressure solutions. From agricultural equipment to locomotives to medical devices, Gems products make a difference in the world you interact with every day. Gems Sensors offers OEM manufacturing services to meet the quality, quantity, and cost objectives of your product, assembly or system. They have the necessary in-house capabilities to manufacture short-runs to mid or high volumes of your custom liquid level, pressure, and flow sensors, as well as switches and solenoid valves, with short lead times.

Quality Products & Service Levels

Competitive Pricing Structures

Excellent Delivery Schedules

Ultra-Fast Response Times

Free Technical Support

OEM & Custom Configurations

Tailored Stocking Profiles

Servicing & Assembly Capabilities