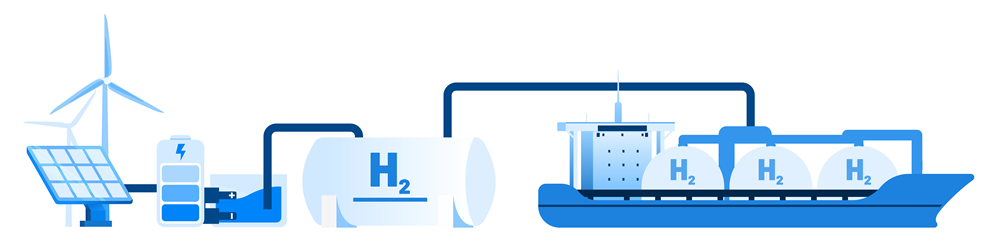

Hydrogen is considered a strategically important future technology for reducing CO2 emissions in industry and transport across the globe. The colourless gas can be produced easily and in an environmentally friendly manner and, in some cases, stored or transported utilsing existing infrastructures.

The Hydrogen Colour Spectrum details the production method used to produce Hydrogen, ranging from methods with absolutely no greenhouse gas emissions (such as Green Hydrogen), to ones that can be considered less environmentally friendly (such as Black and Brown Hydrogen).

At Boiswood, we're committed to working with all our partners towards delivering a positive impact on the environment by delivering end users with the best hydrogen solutions available on the market, no matter the method of production or specific application challenges.

There are an extensive range of Hydrogen applications coming through on the market, often with highly demanding working pressures and temperatures, in demanding operating environments. It is often the case that the most caution regarding the selection of instrumentation and valves for Hydrogen applications, stem around Hydrogen's ability to permeate the surfaces of common metals (embrittlement). However, in applications such as Hydrogen Filling Stations or Thermochemical Water Splitting, extreme pressures and temperatures add extra difficulties into the mix, sometimes making it difficult to specify components that cover all requirements.

We have an extensive range of products specifically designed to combat these 'extreme' pressure and temperature requirements, whilst being specifically designed for operating with Hydrogen media. Some of the typical applications we support include:

Often in Hydrogen applications there are stringent requirements for various approvals, including ATEX directives for explosion-proof or instrinsically safe environements, as well as EC79 type approval specifically for automotive applications.

Today, technological developments, the rapid decline in the cost of renewable energy sources and an urgent need to dramatically reduce greenhouse gas emissions all combine to open new possibilities for Hydrogen use. Hydrogen is currently enjoying a renewed rapid growth in attention, both in the UK and around the world. With the ability to be used as feedstock, fuel and for energy carriage and storage, the gas has many possible applications throughout a multitude of industries.

Most importantly, Hydrogen emits no Carbon Dioxide and creates very minimal air pollution when in use – making it one of the most effective solutions when it comes to decarbonising industrial processes and economic sectors where carbon reduction is both urgent and hard to achieve. It’s clear that Hydrogen has an essential part to play in supporting international commitments to reach carbon neutrality by 2050 and in the global effort to implement the Paris Agreement whilst working towards zero pollution.

Some of our core product solutions include:

To find out more about how we can help you, please contact our experienced engineers today.