Our pressure gauges (mechanical pressure measuring instruments) for gauge, absolute and differential pressure have been proven millions of times over. For the optimal solution for the widest range of applications, there is a choice of measuring systems in bourdon tube, diaphragm element and capsule element technologies.

Bourdon Tube Pressure Gauges

The bourdon tube measuring principle is one of the most commonly know and widely used type of mechanical dial pressure gauge available on the market today. We break our bourdon tube dial gauges down into the two most requested construction materials:

Brass Pressure Gauges

Or sometimes referred to as copper alloy pressure gauges. These pressure gauges are suitable for liquid and gaseous media, so long as they are not highly viscous or crystallising and do not attack the copper alloy parts. The scale ranges typically cover pressures from 0.6 to 1,000 BAR. These instruments are manufactured in accordance with the European standard EN837-1 for most models.

One of our most popular models includes the standard 111.10 brass pressure gauge as one of the most cost-effective options available on the market.

Stainless Steel Pressure Gauges

The wetted parts are manufactured entirely from stainless steel and make them highly suitable for use as high pressure gauges. Again, they are suitable for gaseous and liquid aggressive media that are not highly viscous or crystallising, but also better suited for aggressive environments. They are suitable for scale ranges from 0 to 0.6 to 0 to 7,000 BAR. Depending on the pressure range and the instrument model, overload safety of up to a maximum of 5 x full scale value is possible whilst still maintaining the measurement accuracy. Liquid filling of the case ensures a precise instrument display, even with high dynamic pressure loads and vibrations.

One of our most popular models includes the 232.30 full safety pressure gauge, available in many standard configurations from stock at Boiswood.

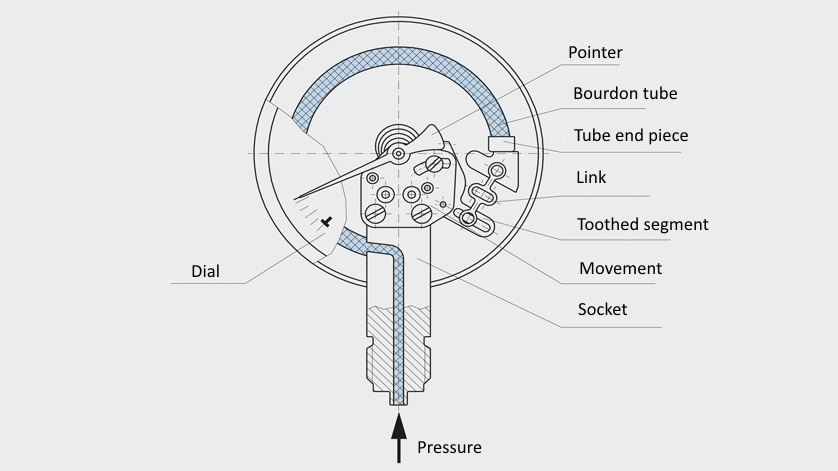

Bourdon tube pressure gauges are the most frequently used mechanical pressure measuring instruments. Their pressure element is often referred to as a Bourdon tube: The French engineer Eugène Bourdon made use of this functional principle in the middle of the 19th century. It is based on an elastic spring, a c-shaped, bent tube with an oval cross-section (as illustrated below):

When the internal space of the Bourdon tube is pressurised, the cross-section is altered in a circular motion. The hoop stresses that are created in this process increase the bend radius on the c-shaped tube. As a result, the end of the tube moves by around by approx.. 2 or 3 millimetres. This deflection becomes the measurement of the pressure, as it is transferred to a movement, which turns the linear deflection into a rotary movement and, via a pointer makes this visible on a scale.

With the c-shaped bent Bourdon tubes, pressures up to 60 BAR can be displayed. For higher pressures, helical or spiral-type Bourdon tubes are used. Depending on the geometry, material and material thickness, pressures up to 7,000 BAR can be shown using the same principle.

For a brief overview of how bourdon tube gauges work versus diaphragm type designs, please watch our informative video below:

Calibrated Pressure Gauges

We can provide a huge selection of our pressure gauges with various calibration certificates and standards, depending on the requirement of the market, application and end-user. We can offer pressure gauges with 3.1 calibration certificates (with calibration values listed) according to the manufacturer’s standard, or we can work specially to requirements of UKAS and DKD/DAkkS accreditations.

One of the most popular types of pressure gauge required with calibration certificates includes our range of test gauges:

Test Pressure Gauges

These are often required for the highest accuracy requirements, depending on the instrument model, accuracies of 0.1, 0.25 or 0.6% of full scale value can be measured. The pressure ranges cover from 0 to 6 mBAR to 0 to 1,600 BAR, making them suitable for either low or high pressure applications. For each of the pressure gauges within this category, a DKD/DAkkS certificate can be provided, making them very popular for calibration tasks in R&D and test & measurement settings.

One of our most popular models includes the 332.30 test pressure gauge which is available with Class 0.6 accuracy, pressures up to 1,600 BAR and calibrated with test certification.

The WIKA calibration laboratory has been accredited for pressure for almost 40 years and for temperature for almost 30 years. For pressure measuring instruments we can offer fast and precise manufacturer independent calibration:

- For -1 BAR to +10,000 BAR instruments with calibration using working standards (precise electrical pressure measuring instruments) or high-accuracy reference standards (pressure balances).

- With an accuracy down to 0.003 % of reading for the standard used.

- DAkkS accredited (in accordance with DIN EN ISO/IEC 17025), as well as in accordance with the directives DIN EN 837, DKD-R 6-1 or EURAMET cg-3.

- Certified to ISO 9001 and ISO 14001 with high qualified, individually trained personnel using the latest reference instruments with the highest accuracy.

Since 2014, the calibration laboratory has also been accredited for the electrical measurands DC current, DC voltage and DC resistance. Since 2020, the calibration laboratory has also been accredited for force measurement.

For an overview on the differences between factory and traceable calibration standards, please watch our video below:

Diaphragm Pressure Gauges

The application areas for diaphragm pressure gauges are very versatile. They are the specialists in the process industry when it comes to critical measuring tasks such as with highly corrosive or viscous media or when it comes to low pressures and high overload. They often come into play when the bourdon tube pressure gauges reach the limits of their performance.

The scale ranges are from as low as 0 to 16 mBAR to typically 0 to 25 or 0 to 40 BAR. Depending on the pressure range and the instrument model, overload safety of 3 x or 5 x full scale value is possible as standard, making them highly suitable for accurate low-pressure measurements. For special designs, an overload safety of up to 400 BAR is possible, with the measurement accuracy maintained.

Diaphragm pressure gauges are even suitable for highly viscous or contaminated media by using an open connecting flange (per DIN/ASME). For measuring particularly aggressive media, the complete wetted surface can be lined with a large selection of special materials (e.g. PTFE, Hastelloy, Tantalum, and many more exotic alloys or elastomers).

One of our most popular models includes the 432.36 diaphragm pressure gauge which features the high overload pressure to 400 BAR, whilst still being able to accurate measure down at ranges as low as 16 mBAR. Also within or product range is a complete line diaphragm seal systems which are highly popular for pharmaceutical and medical applications where cleanliness standards are critical.

Capsule Pressure Gauges

These capsule measuring instruments are particularly suited to gaseous media at very low pressure ranges. The scale ranges are between 0 to 2.5 mBAR and 0 to 1,000 mBAR in accuracy classes from 0.1 to 2.5.

Capsule pressure gauges consist of two circular, corrugated diaphragms, joined together around the edge with a pressure-tight seal. Overload protection is possible in certain cases where required.

These capsule pressure gauges are used mainly within medical, vacuum, environmental and laboratory technology for critical contents measurement and filter monitoring.

One of our most popular models includes the 632.50 capsule pressure gauge which is available with ranges down to 2.5 mBAR and nominal dial sizes up to 160mm.

Differential Pressure Gauges

Differential pressure gauges work with a wide range of pressure elements. With this variety, measuring ranges from 0 to 0.5 mBAR to 0 and 1,000 BAR and static overlay pressures up to 400 BAR are possible.

These measuring instruments are commonly used to monitor:

- The pollution degree in filter systems

- The level in closed vessels

- The overpressure in clean rooms

- The flow of gaseous and liquid media

- Control of pumping plants

One of our most popular models includes the 732.14 differential pressure gauge which is widely popular in process industry with overload safety up to 650 BAR.

Also within our product range is the latest air2guide product family for heating, ventilation and air conditioning (HVAC) applications. This product family offers a comprehensive range of filter and ventilation monitoring systems, including differential pressure gauges (mechanical and electronic) for filter monitoring, incline tube manometers, differential pressure switches, differential pressure transmitters and air flow velocity transmitters for measuring the volume flow and air velocity in air ducts.

Absolute Pressure Gauges

Absolute pressure gauges are used when measured pressures are independent of the natural fluctuations in atmospheric pressure.

The pressure of the measured media is determined against a reference pressure, which corresponds to the absolute pressure zero point. For this, the reference chamber is completely evacuated, so that there is a near-perfect vacuum in it.

Applications for these high-precision measuring instruments are, for example, monitoring of vacuum pumps and vacuum packaging machines. They are also used in laboratories, in order to monitor condensation pressures or to determine the vapour pressure of liquids.

One of our most popular models includes the 532.52 absolute pressure gauge which is ideal for low pressure measurement down to 25 mBAR with a high overload safety feature.

Digital Pressure Gauges

Digital pressure gauges are available from our range in a few different variations. These can be split out into complete digital pressure measuring solutions, dial pressure gauges with output signals or dial pressure gauges with switching contacts:

Precision Digital Pressure Gauges

High-quality and precision digital pressure gauges are suitable for stationary and also mobile measurement and display of pressures. In addition, a digital pressure gauge can be used as a pressure reference and enables the easy testing, adjustment and calibration of other pressure measuring equipment directly on-site. Through efficient measuring cells with electronic linearisation of the characteristic curve, a high accuracy is achieved.

One of our most popular models includes the CPG1500 digital pressure gauge which boasts a high accuracy to 0.025% and can be equipped with integrated data logger or data transfer (wireless) functionalities.

Pressure Gauges with Output

The multi-functional product line of intelliGAUGEs present a cost-effective and, at the same time, reliable solution for nearly all pressure measurement applications. They combine the analogue indication of a mechanical pressure gauge, needing no external power, with the electrical output signal of a pressure sensor. These hybrid instruments are available with all commonly used electrical signals.

The sensor works in a non-contact way, without any influence on the measuring signal. Many instruments are available in versions for use in hazardous areas. Depending on the pressure gauge model, many output signals are available including 4 to 20 mA, 0.5 to 4.5 V Ratiometric, 0 to 10 V and more. For pressure gauges with nominal sizes 100 and 160 mm, the electrical output signals can also be combined with switch contacts.

One of our most popular models includes the PGT23 output pressure gauge which combines all of the safety features and specifications of our bourdon tube pressure gauges, with the modern electrical functionality of a pressure sensor.

Contact Pressure Gauges

As control systems are gaining more and more importance in industrial applications, having a stand-alone visual pressure indication on the measuring instrument itself is no longer sufficient. More customers now require the measured value must be transferred to the control system via an electrical signal, e.g. by closing or opening of a circuit.

All instruments with inductive contacts are certified in accordance with ATEX Ex ia. Depending on the model selected, units are available with different contact type including magnetic snap-action, inductive, electronic, reed, micro and transistor.

One of our most popular models includes the PGS23 contact pressure gauge which combines all of the safety features and specifications of our bourdon tube pressure gauges, with the modern electrical functionality of a pressure switch.

Not sure if you need contact gauges or pressure switches? Watch our overview video below to highlight the differences:

How to Select a Pressure Gauge

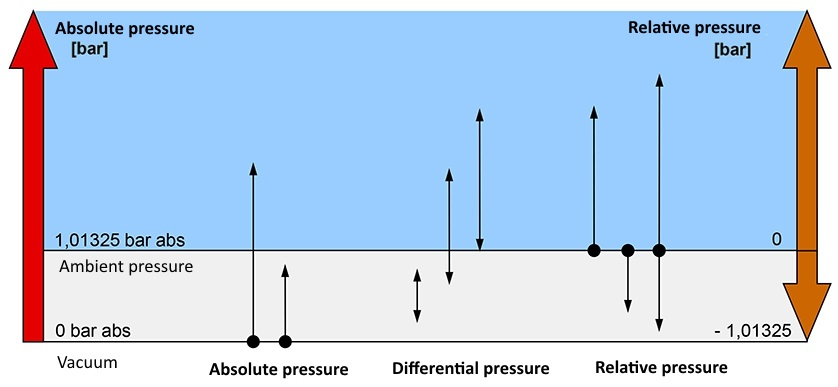

Within the selection criteria for pressure gauges, type of pressure takes the top priority. The measurement of gauge pressure, in fact, reliably fulfils the purpose with most processes. However, for numerous applications in industry, pressure gauges for absolute or differential pressure come into consideration.

These three main types of pressure considered for pressure gauges are simply defined as:

- Gauge (G) – is measured in reference to atmospheric pressure.

- Absolute (A) – is measured in reference to vacuum.

- Differential (D) – is measured across two different points within a system.

For more information on the different units of pressure measurement and how to select which type you need, click here to visit our “Types of Pressure Measurement” blog.

Application Specific Pressure Gauges

Within our extensive portfolio of different technologies, measuring principles and base models to choose from, we can recommend specific choices based on the application, industry or operating environment/process conditions.

UHP Pressure Gauges

Including models such as the 230.15 UHP pressure gauge available with FaceSeal/VCR end connections, 316L SS (VIM VAR available) extrude hone/electropolished construction material and cleaned with double bagged according to SEMI specifications. These are highly popular in semiconductor processing and manufacturing applications.

Air Compressor Pressure Gauges

Including standard bourdon tube design models such as the 111.10 brass pressure gauge and 232.30 stainless steel pressure gauge with quick off-the-shelf configurations at cost-effective price points. These are widely used in both industrial and hydraulic applications.

Diaphragm Seal Pressure Gauges

Such as the model DSS10M or DSS10T depending on preference of threaded or flanged connections. These are widely used in oil & gas, chemical & petrochemical, pharmaceutical applications where there is particularly aggressive, corrosive or toxic media, or where there are specific cleanliness standards required for operation.

Whatever your requirements, are technical specialists are always happy to help you find the optimal solution for your needs.

Your WIKA Gauge Partner

Our enormous portfolio features an extensive range of options, technologies and configurations to meet the most demanding applications. To explore our full range of product solutions from WIKA, please visit our landing page here.

For technical support on selecting the right pressure gauge for your application, get in touch with our experienced engineers here.