Our single point level sensors are ideal for reliable and accurate tank level detection. Our liquid level sensors are available in a vast range of sizes, mountings, materials and sensing technologies (from mechanical to no moving parts) which include float type sensors and switches, electro optic level switches, capacitive level sensors and switches and ultrasonic level sensors.

Level Measurement Technologies

Point level sensors are often used as a warning indicator to trigger an alert when a fluid level is either too high or too low within a tank or vessel. A single point level sensors detects if a predetermined single liquid level is reached and actuates a switch to notify a user.

To date, we have supplied and supported several different level sensing technologies including:

- Float Level Sensors – A float level sensor contains a float magnet that travels freely along a stem as the level of liquid rises or falls, and a switch is activated based on the magnetic field that is generated. Some of our most popular OEM level sensor models include the LS-3 compact level sensor and the LS-7 side mounted level sensor.

- Electro Optic Level Sensors – Our optical liquid level sensors feature a small footprint for anywhere space is at a premium. Solid-state switching delivers dependability over a long service life. Our most popular optical level sensor models include the ELS1100 general level switch and ELS950 rugged level switch for harsh applications.

- Ultrasonic Level Sensors – Our ultrasonic switches are non-contact, and work by emitting high frequencies that are reflected back and measured. All our ultrasonic transmitters and switches are ideal for applications requiring solid-state level measurement such as those with ultrapure, dirty, coating, scaling or corrosive-type liquids. Our most popular model is the XLS-1 ultrasonic level sensor which is suitable for many applications where condensation could be an issue, including water tanks, radiators, printers and other industrial settings.

- Capacitive Level Sensors – Our capacitance sensors are frequency-tuned for liquid detection. Most of these are non-contact models that sense from outside a fluid vessel's wall and offer adjustability to operate accurately with both aqueous and non-aqueous liquids. Our most popular unit is the model CAP300 level sensor which is one of the most durable and reliable point sensors available on the market.

- Water in Fuel Sensors – Our water in fuel switches are designed to detect the presence of water in fuel tanks and filters. It is a solid-state no moving parts sensor that is suited for off-highway vehicles, locomotives, and generator sets.

Liquid Level Sensors

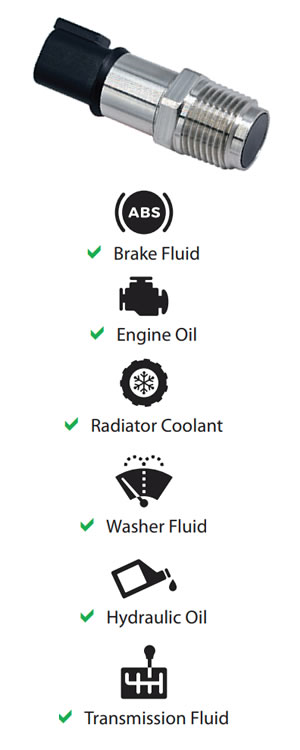

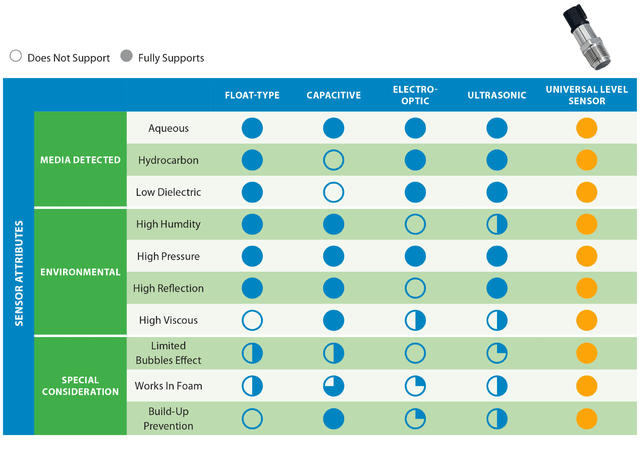

Introducing the ULS-100 Universal Level Sensor, due for release in May 2022, we will have available this new all-in-one level sensor technology developed for the most rugged aqueous, oil and hydrocarbon-based applications.

Great for Outdoor Use & Harsh Environments

The sealed construction meets a phenomenal IP6k9k rating for high-pressure wash-downs. It covers a wide temperature range of -40°F to +185°F (-40°C to +85°C) and a high-pressure range of 300 PSIG (20 BAR) to meet the most extreme conditions. Shock and vibration resistance makes this level sensor the top choice for any automotive or mobile applications.

Build-Up & Coating Resistant

The unique sensing element is constructed of reinforced a PBT/ PC blend, and it features a flush face design. This bespoke material and critical flush surface design reduces any false signals caused by coating and build-up that often affect other sensor types, such as electro-optic.

No Moving Parts

The sensor utilises a solid-state open collector output for point level sensing with high accuracy and repeatability. Without any mechanical moving parts, the sensors operational lifespan is greatly increased compared to other technologies, such as float-type switches which can be prone to “wear” and may fail over time.

One Sensor, One Solution

The ULS-100 level sensor is designed specifically to work well with a several different types of media, including brake fluid, engine oil, radiator coolant, washer fluid, hydraulic oil, transmission fluid and more. It eliminates failure caused by moving parts and works well in highly viscous, high pressure, humid and reflective applications. It does not rely on specific gravity or conductivity.

This unit has been expertly developed to simplify product selection and reduce your inventory with ONE common sensor type to replace them all.

To read more about the various features and benefits of this new level sensor technology, please visit our ULS-100 product overview by clicking here. For a brief introductory overview on the sensor, please watch our short video below:

Level Sensor Applications

Keeping a focus on our new ULS-100 universal level sensor, this is one singular sensor that has been designed to fit in many critical applications and industries, including construction, emergency vehicles, buses & recreational vehicles, agriculture, water & wastewater treatment, power generation, renewable energy, HVAC/R and more.

The endless features & benefits and competitive advantages of the unit make it the only ideal choice for aqueous, oil and hydrocarbon-based applications. Three of the key example cases that have been proven already include:

- Vacuum Trucks - vacuum trucks are used for the safe extraction and transport of wastewater. Accurate, reliable level detection of various fluid types is required from windshield washer fluid to high-pressure hydraulic oil.

Finding a single liquid level sensor, with no moving parts, that will reliably detect various media such as hydraulic fluid, engine oil, fuel, coolant as well as tank water and will endure high vibration with limited available space present in vacuum trucks. Vacuum extractors require feedback on the status of all fluid level containers on their vehicles, but they struggle with the different types of sensors required. The manufacturer and fleet maintenance potentially need to buy and stock several different styles of these liquid level sensors. Many different part numbers, in lower volume, lead to increased costs and add to stocking and replacing more parts than needed.

The universal level sensor does not rely on the characteristics (for example varying specific gravities) of the fluid to detect its presence or absence. It will reliably detect most any liquid. With its robust stainless steel compact housing, IP6k9k rating (direct pressure wash-down spray), and wide operating temperature range, the Universal Level Sensor is perfect for the most demanding conditions often present in Vacuum extraction equipment. Having one dependable sensor, with no moving parts, to replace the many types often required will overcome common functional and conditional limitations, ease product selection and reduce inventory.

- Wind Turbines - the critical components and systems that make up a wind turbine need to be reliable. One common factor that limits useful life of these systems is continued stress on bearings, brakes, and gears. It is important to maintain proper fluid levels for optimal sustained performance, and to prevent occurrences that may result in expensive damage.

Finding a single liquid level sensor, with no moving parts, that will reliably detect gearbox oil, brake fluid, hydraulic oil, and will endure the vibration & temperature conditions found in a wind turbine nacelle. Vibration, temperature, humidity. These are all conditions to carefully consider when choosing level sensors for the various systems of a wind turbine. These sensors are expected to provide continuous trouble-free operation. The expense and extreme effort involved with maintaining these turbines is substantial, and downtime can be very costly. There are different type sensors currently used, but each has its own specific limitations.

The universal level sensor does not rely on the characteristics (for example varying specific gravities) of the fluid to detect its presence or absence, and it has no moving parts to wear out or damage. It will reliably detect most any liquid, and it resists coating and build up. With its robust stainless steel housing, IP6k9k rating, resistance to vibration, and wide operating temperature range, the universal level sensor is perfect for the conditions present in the turbine nacelle. Its small footprint and non-intrusive sensing element fit nicely where space is critical.

- Hydraulics - hydraulic lift systems are used to raise and lower an arm on a shearer (also called a power loader) to cut coal from the coalface. Reliable hydraulic oil level sensing is required to maintain continuous operation efficiently and safely.

Hydraulic oil coating the prism on optical sensors causes inconsistent sensing of critical fluid level creating concerns over reliability. The sensor is unable to accurately detect fluid levels. Optical type sensors used in these applications are subject to coating build-up and other reliability concerns due to the LED refraction technology used. Coating present on the prism can prevent repeatable detection of hydraulic oil level, limiting the sensor’s accuracy.

The universal level sensor tolerates coating with a flush PBT/PC blend sensing face. Its compact, rugged construction features a durable IP6k9k sealed design and a wide temperature range for use in harsh environments. This sensor was developed with extreme aqueous, oil and hydrocarbon applications in mind.

Other Level Sensors and Level Switches

Whether you require single point level sensors, multiple point level sensors or continuous level meters or transmitters, we can help you with a suitable solution. To explore our full range of level monitoring products, please visit our category page here.

For technical support on selecting the right component for your application, get in touch with our experienced engineers here.